Products & Capabilities

For over 80+ years, K. Wm. Beach Manufacturing Co., Inc. has offered its customer's quality die cut products to the automotive, aircraft, and appliance industries. Today, the services have expanded to include automotive and motorcycle subassemblies, as well as automotive interior trim.

Services

Our die cutting business is service oriented based on our customers' manufacturing and material needs. Ranging from 25 ton to 500 ton, our presses have the ability to cut a variety of materials in sheet fed and rolled form. Our experience includes, but is not limited to, spare tire covers, sound deadening material, interior automotive trim, and gaskets. We meet specialized fabrication needs such as silk screening, slitting, metal fabrication, and sonic welding.

In addition, K. Wm. Beach Manufacturing Co., Inc. offers JIT labor for the completion of automotive and motorcycle sub assemblies. We are able to meet successfully the demanding quality standards and deadlines that are inherent in the automotive and motorcycle industries.

Capabilities

Clean Room

- 3500 Square ft. Full Clean Room

This building is ISO Class 8 Certified - 3500 Square ft. Semi-Clean Room

General Assembly

- Powertrain Assembly

- IAFM's

- Turbo Horn

- Water Valves

- Safety Related

- Brake/Gas/Power Steering Components

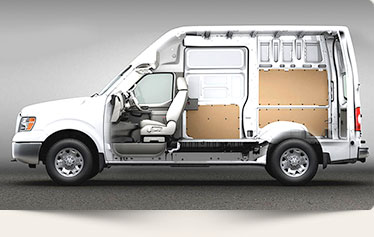

Interior Trim Assemblies/Components

- Head Liners

- Bus Floors

- Load Floors

- Stiffeners

- Foam Stuffers

- NVH Components

Other Processes/Assemblies/Die-Cutting

- Kiss Cutting

- Routing

- Silk Screening

- Ultra-sonic Welding

- Adhesive Wet, Hot Melt, PSA

- Laminating

- Sorting and Inspection

- Sequencing/Picking/Packing Operations

Die-cutting - Rolled Goods or Sheet Material

- Wood

- Panelboard

- Fiberboard

- Plastic Solid/Extrusions

- Shoddy Pad

- Corrugated Plastic/Cardboard

- Foam

- Rubber

- Cork

- Insulation Material

- Tapes

- Weatherstripping

- Automotive Carpet

- Spare Tire Covers